KubeStart

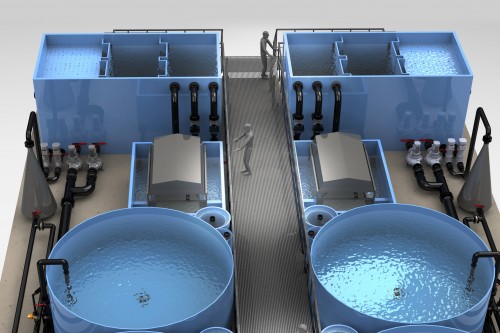

KubeStart is a complete and energy-efficient recirculation system that ensures stable, clean water and low energy consumption in modern aquaculture facilities.

KubeStart uses a proven moving bed biofilm reactor (MBBR) as a biological filter, combined with UV treatment, ozonation, particle removal, and oxygenation. This technology ensures excellent contact between water and biofilm, effectively removing ammonium and organic matter, and maintaining a stable and healthy aquatic environment for the fish.

Optimal gas balance and particle management

The system’s aerator provides efficient CO₂ removal through countercurrent aeration, while particles such as waste and uneaten feed are quickly removed using efficient hydraulic solutions and dual water outlets. Mechanical filtration with a 40 μm microscreen ensures that the water returning to the tanks is clean and free from harmful particles.

Integrated cooling and heating

With a built-in reversible heat pump, KubeStart can both cool and heat the water to maintain optimal temperature. The system is designed for temperature ranges from 1 to 21 °C and can adjust the water temperature by up to 10 °C within 48 hours. All control and monitoring are integrated into an advanced PLC system to ensure safe operation.

Smart control and safety

KubeStart features a fully integrated control system with touch screen for easy monitoring of oxygen, pH, temperature, gas saturation, and water level. The PLC system automatically adjusts pump speeds, logs data, and issues alerts via alarm, SMS, or phone call in case of deviations. A UPS ensures operation during power outages, maintaining control and alert functions.

Energy-saving and cost-efficient

All electric motors are equipped with frequency control, reducing energy consumption by 30–50%. The heat pump requires only 4–5 kW to maintain the desired water temperature, resulting in 50–55% lower energy costs compared to traditional flow-through systems with a heat pump. Over time, this can represent substantial operational savings.

Modular and user-friendly

KubeStart is delivered as prefabricated modules in durable, chemical-resistant polypropylene, fully tested and ready for use. The compact, integrated solution allows for easy installation and hygienic cleaning.

Key benefits

- Complete and reliable recirculation system

- Efficient biological filtration with MBBR

- Advanced particle and gas control

- Integrated cooling and heating with heat pump

- Smart, automated control with alarm and notification system

- Low energy consumption and reduced operating costs

- Easy installation and maintenance with modular design

Want to learn more about KubeStart?

Call Vebjørn at +47 970 64 180 or send an email to vebjorn.andreassen@alvestadmarin.com